Treatment of wastewater from tanning process

Leather has always kept the heat by elegance and luxury that it gives leather shoes, handbags, wallets, belts, clothing leather, furniture, etc. The previous article mentioned the extremely complex tanning process to produce quality final leather, but never mentioned how to handle the waste released during tanning process. Today, I'm going to introduce you to a highly effective tanning waste treatment.

Source of tanning waste

Most of the stages in tanning technology are wet processes, so the amount of wastewater generated is huge. Contaminant content depends on the amount of chemicals used and the amount of substance removed from the skin. In the maintenance stage, the waste contains contaminants and animal grease. In the pre-treatment of skin by salt, wastewater is yellow and contains soluble protein such as albumin (pH = 7.5 - 8) and suspended solids and has high concentration of NaCl. Therefore, this process decays fastly decay. Wastewater in the lime soaking and hair removing contains alkaline, high level of protein due to the skin dissolved in water, and nitrogen in the form of ammonium or ammonia. Wastewater in the foaming step is high acidity due to the use of sulfuric, acetic, formic acid. Wastewater is acidic and contains high levels of Cr3 + in the tanning step.

Pollution of tannery waste water

Tannin wastewater generally is high in color level, TS solid, SS suspended solid, organic BOD pollutants. The alkaline waste streams are part of lime soaking, hair removing. Wastewater in foaming stage is acidic. Wastewwater from tanning stage also contains sulfur, chromium, and grease.

Technology of tanning

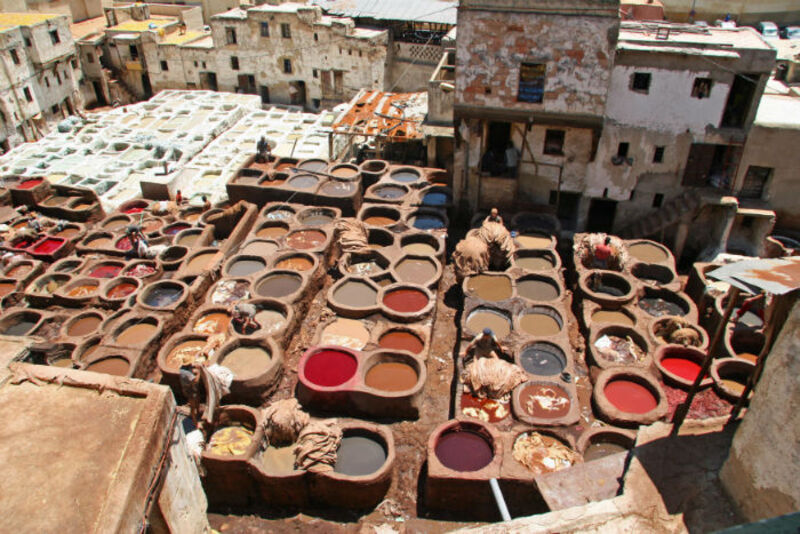

The fashion industry currently consumes about 65% of the world's used leather. In many places, tanning is the most polluting sector. Since the Middle Ages, leather processing facilities have always been isolated from densely populated areas. Today, the tanning industry uses chromium, carbon dioxide compressed into high pressure presses, the skin is spinning in that vase and carbon dioxide will cause chromium to penetrate deeply into the skin layers, This is a bit cleaner, but chromium is a heavy metal which is toxic to the environment.

Wastewater from the factories must be separated into different waste streams in the process of tanning by chromium. The wastewater from the dipping and the chrome flowing through the trash is put into the air conditioning tank, so do the wastewater from other stages such as washing, dye, etc.... In the air conditioning tank, aeration system will be used to control the flow, concentration and anti-sludge. The sewage pump will pump water to the oil tank to remove the oil. The water then continues into the anaerobic digestive tract and activated sludge. The microbial gas supply in the arotank tank is carried out by a gas blower. The activated sludge of the aerotank continued to flow through the second settling tank. After more than 2 hours of settling, the activated sludge subsided and the clear water in the upper part of the tank flowed into the contact tank. Chlorine is used to disinfect water when discharging into the sewer system. The residual sediment from the second settling tank is released into the slurry reservoir and the rest circulates the aerotank. The sludge in the muddy tank disinfects the sanitiser before pumping through the mud drying yard or mud press to remove the water.

In 2014, the first new industrial tannery factory was built. A patent for carbon fiber dyeing was registered 15 years ago. Similar to leather tanning, CO2 is used to replace water during dyeing: CO2 absorbs dye molecules and makes the dye permeate the fabric. This dye method is faster, water saving and 90% of CO2 used in dyeing can be recycled. At present, some enterprises have applied dry dyeing method.