Application of 3D technology in Vietnam footwear industry

The footwear industry started to apply 3D technology in many stages of footwear production, helping to reduce the time and cost, thereby improving productivity and product quality. The application of 3D technology in particular or the application of information technology in general will help save time in the design process and creating continuous product samples to meet the increasing tastes of consumers. Today, 3D technology is an essential tool for shoe manufacturers to improve the quality of their products and to create quality products that contribute to the competitiveness of international companies.

Over the years, the footwear industry is one of the key sectors in the economic development. In addition to the development of materials for shoe making, quality improvement and information technology applications such as 3D in designing - the most important stage in the making process made a breakthrough in the footwear industry.

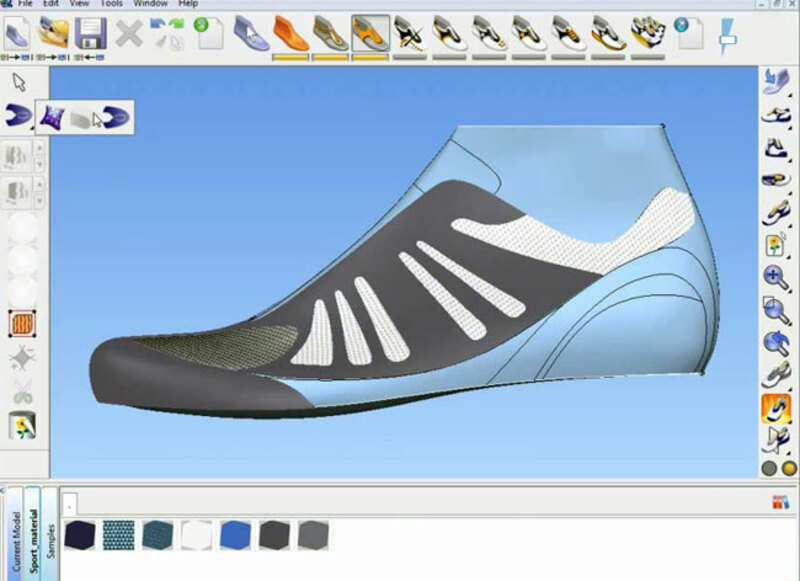

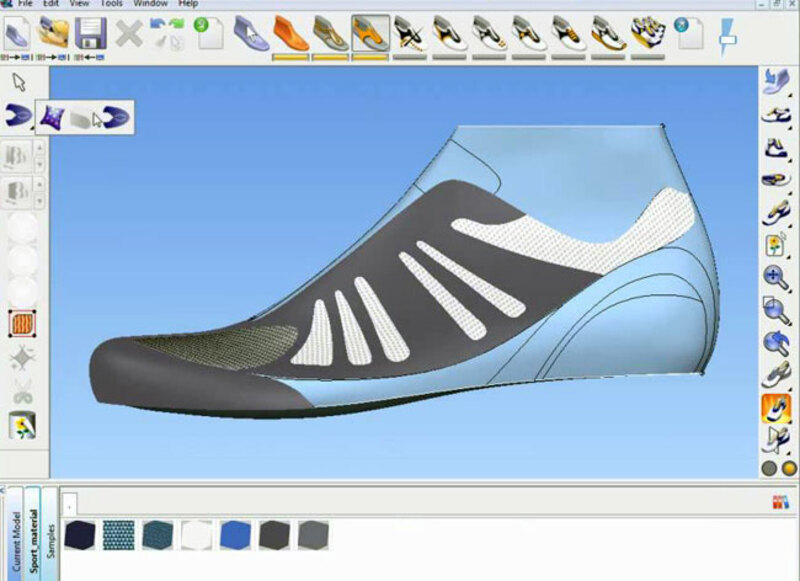

Among all of the 3D printing softwares, 3D ShoeMaker Pro is highly appreciated by industry experts and businesses. This software is easy to learn and use, takes less time and costs than other softwares, shortens the production process of shoes form, digitizes 3D data, or imports files from other 3D design software.

Using ShoeMaker Pro software in designing shoe's surfaces with major functions such as drawing lines on the surface, applying color, materials, effects, thickness and bulge of the reinforcing parts, The combination of shoe form, shoe tip, 3D-2D shoe sole can interact with other technologies such as LastMaker, Engineer, Shoecost and Pattern cut, all are contained in one only "shoe" file. In addition, ShoeMaker Pro will create realistic 3D shoe models without the cost of modeling, production defects and it can create complex designs, create subsave and save them to the accessory library.

The main application of 3D printing technology in the footwear industry is for printing shoe soles as used in prototyping, sample testing and silicon molding, PU molding, or called shoe sole making tool. Using this technology will reduce 13 hours compared to traditional printing, and can help manufacturers reduce the time and costs. As a result, this improves the productivity, product quality and promoting the creativity of the designers.

It is clear that, with the development of materials for shoe making, quality improvement, and process technology to ensure the environment, the application of information technology in the design creates a change that is critical to the footwear industry.

In the present stage, together with the development of fashion and scientific and technological achievements, designers have to constantly innovate. Therefore, improving the design capacity of the footwear industry is a necessary activity to meet the tastes of domestic and foreign markets.